The topic of Supply Chain Management is currently very covered. Why do you think it is more covered than usual?

Today this is amazing to hear journalists, business people, politicians talking about this topic of Supply Chain Management (SCM). We see as well articles published by top tier business schools and consulting firms are blooming. It seems that people almost discover how critical supply chain management is. We hear words such as supply chain, logistics, shortage = out of stock, missing parts, uncertainty, disruption, relocalization of production operations (the famous local made in) but there are potential confusions between those words.

Generally, top managers discover SCM when it is too late, that means when companies face crisis.

For me, who has been working more than 30 years in supply chain management and logistics, this is always the same story. Generally, top managers discover SCM when it is too late, that means when companies face crisis. It is a matter of fact, visionary top leaders, who have been supporting investments and growth in SCM, are rare.

Agility and resilience in supply chains

All concepts of SCM and ideas, which are developed in that article, except the inventories, can be applied to the service industries such as banking, insurance, software, professional services, legal firms,…

The major stakes related to SCM are not the same in the crisis phase, the recovery phase, and especially between the old normal and the new normal. Here, I focus on the new normal.

The major stakes related to SCM are not the same in the crisis phase, the recovery phase, and especially between the old normal and the new normal. Here, I focus on the new normal, which will be characterized by a higher agility and a stronger resilience.

Some key preliminary definitions

A Supply Chain (SC) is made of activities or operations with stocks everywhere. We can differentiate:

- An internal vs external SC

- An upstream side vs a downstream side

- The level of fragmentation vs integration

- The local presence vs the global one

A SC model derives from the value chain design, which is the outcome of a strategic process (make/buy, production and supply footprint, distribution channels,…) by answering to the 4 main questions: who does what and where and how?

As a conclusion, the more fragmented and the more global the SC is, the more complex the SC management will be.

The Supply Chain Management is monitoring process from customer offer formalization, then demand planning, and then, supply planning.

The Supply Chain Management is monitoring process from customer offer formalization (value proposition of your business model), then demand planning, and then, supply planning. The Sales and Operations Planning (S&OP) is the key backbone of SCM by reconciling the demand to the supply sides while optimizing the stock levels.

Value creation by SCM and trade-off

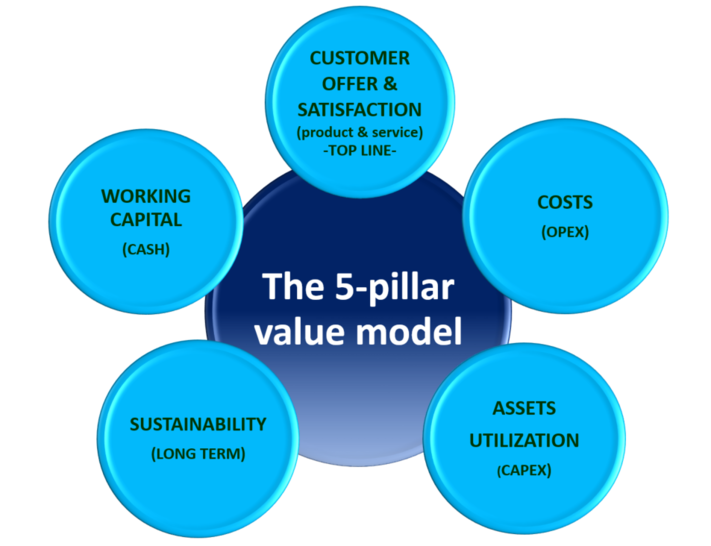

If you want to avoid discovering the benefits of SCM in a crisis mode, this is key to focus on the positive value generated by SCM. I call it the value roadmap based on the 5-pillar value model.

The selection of the value-pillars you decide to focus on and their prioritization should depend on your strategy.

New normal environment

The SC patterns and the SCM priorities and solutions will depend on the ecosystem we are. In the new normal, I point out 3 main characteristics:

1. Demand pattern evolution:

o The quality of the demand: we can imagine that the customers’s needs should respect the notion of fair value. The purpose of SCM will be to fulfil the needs of customers; no more, no less, and those needs will be basic.

o The volume of the demand characterized by a higher volatility and uncertainty

2. Value priorities according to the 5-pillar value model

3. Cash limit

The key principle is to connect demand to supply and strategy to operations.

I consider companies should focus on the 3 following axis, which are related to the 3 levels of decision (strategic, tactical, operational):

- Design a fair offer to customers integrating and balancing (strategic level):

o Willingness to pay of the customers (demand side)

o Supply chain capabilities in terms of cost and risks to serve those customers (supply side)

- Develop your simulation / optimization capability to test in volume and money:

o SC model scenarios (suppliers footprint, route-to-market, automation,…) (strategic level)

o Supply-Demand planning scenarios through S&OP / IBP (tactical level)

- Invest in the digital to:

o Get real time visibility on the sell-out, the source-in, the stock level,… in terms of volume, money and performance (operational level)

o Integrate tactical and operational planning (both tactical and operational levels)

Watch the webinar in replay: